Maptek workflows can automate and streamline processes for underground and open pit mines, increasing efficiency and making it easy for new users to step into a task.

Maptek workflows can automate and streamline processes for underground and open pit mines, increasing efficiency and making it easy for new users to step into a task.

The complexity of mine planning operations can be broken down into sets of repetitive tasks. Building those steps into logical workflows can optimise the processes and increase productivity for underground and open pit mines.

At one site, an automated open pit workflow reduced an 8 hour process down to about 30 minutes, with minimal user input after starting the workflow.

Maptek Mine Measurement Engineer Nick Ingwers explained that the main objective was to streamline an existing process, which involved switching between Maptek PointStudio, AutoCAD, and Maptek Vulcan.

Detailed standard operating procedures had been written to streamline and complete the task, but this process was cumbersome and required knowledge of several different software programs.

Streamlining the process reduced the back and forth between programs and increased efficiency, taking roughly 1/16th of the time.

Updating as-built maps and site data typically involves around 50 scans, which can be difficult to register simultaneously. Registering the scans separately is arduous. The workflow speeds up the process and efficiently handles large volumes of data.

Reducing the time taken to update as-built maps allowed for faster turnaround times of deliverables to the operations team, who previously waited a day for updates.

Using this workflow weekly to update as-built maps means the site effectively gains an entire day of productivity.

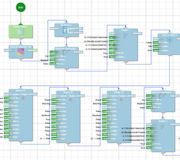

The Workflow Editor accesses all Maptek software tools, and each workflow resembles a flowchart. Progress is easy to follow as the workflow runs, and once built, it runs with the press of a button.

Automating steps

The user imports raw scans, the corresponding survey data, overall mine topographic surface, and as-built toes and crests. The workflow registers and filters the scan data, creates a surface from the new scans and combines that with the existing topography.

Existing toes and crests are then cropped to the boundary of the new area. The user digitises the new toes and crests, and clicks OK. The workflow combines new and existing toes and crests, maintaining data integrity.

Ingwers begins with a scoping call to understand customer needs and project direction before starting work on the shared data. Regular progress calls ensure that everyone knows the capabilities of the Workflow Editor.

Site training is important, and is structured to walk through each step. Users learn how to complete the process manually, ensuring that they understand what the automated process entails.

Explanatory messages appear throughout. Users can easily follow along and run the workflow with limited knowledge about PointStudio or the process, learning as they go.

The training and workflow dialogues provide insight into how workflows are built, allowing users to adjust and potentially build new workflows. Tasks can also be completed by different people, if the usual drafters and surveyors are unavailable.

'This particular customer wanted to completely remove the need for AutoCAD in the task. When I showed them the workflow and how little user input is required, they were immediately impressed that they can do everything in one program,' said Ingwers.

Ingwers will continue to help the site add to the workflow and train users. Ongoing contact, including when PointStudio software updates are installed, will ensure that the workflow is still serving the desired purpose.

Improved efficiency and productivity allows users to spend more time on meaningful analysis, rather than repetitive tasks.

Key Points

- Automating an open pit survey workflow reduces an 8 hour process to about 30 minutes, with minimal user input

- Reducing the time to update as-built maps allows for faster turnaround to the operations team, removing a production bottleneck

- Improved efficiency and productivity frees up users to spend more time on meaningful analysis and interpretation

- Wistia video thumbnail

- Maptek workflows can help automate repetitive tasks and ensure consistent processes are followed across your operation.

More information is available here:

https://www.maptek.com/forge/december_2021/mine_measurement_workflows.html